Mouth guards have long been regarded as an essential element in oral health care. These devices serve the critical purpose of protecting the teeth and jaw against the damaging effects of grinding and clenching, commonly known as bruxism. Over the years, mouth guard manufacturing has witnessed significant advancements and innovative designs that not only enhance the functionality and performance of these dental appliances but also improve user comfort and compliance.

Understanding the Basics of Mouth Guard Manufacturing

Mouth guards play a vital role in oral health maintenance by preventing tooth wear, jaw muscle discomfort, and other related complications. These custom-made oral appliances are typically prescribed by dentists and orthodontists to individuals who suffer from bruxism or temporomandibular joint disorders (TMJ). The manufacturing process involves a meticulous approach to ensure a perfect fit and optimal protection.

The Importance of Mouth Guards for Oral Health

Bruxism, if left untreated, can lead to severe consequences such as tooth fractures, tooth loss, and even chronic headaches. Mouth guards effectively distribute the forces exerted during clenching and grinding, thereby minimizing the risk of damage to the teeth and jaw. These innovative devices act as a protective barrier, allowing individuals to sleep soundly while preserving their oral health.

The Traditional Process of Manufacturing Mouth Guards

Traditionally, mouth guard manufacturing involved taking physical impressions of the patient's teeth to create a mold. This mold was then sent to a dental lab, where technicians would manually fabricate the mouth guards using acrylic materials. Although effective, this process often lacked precision and customization, resulting in less optimal fit and comfort.

However, the advent of digital dentistry has revolutionized the mouth guard manufacturing process, enabling dental professionals to leverage innovative designs and materials to create highly personalized and effective solutions.

The Evolution of Mouth Guard Manufacturing: Embracing Technology

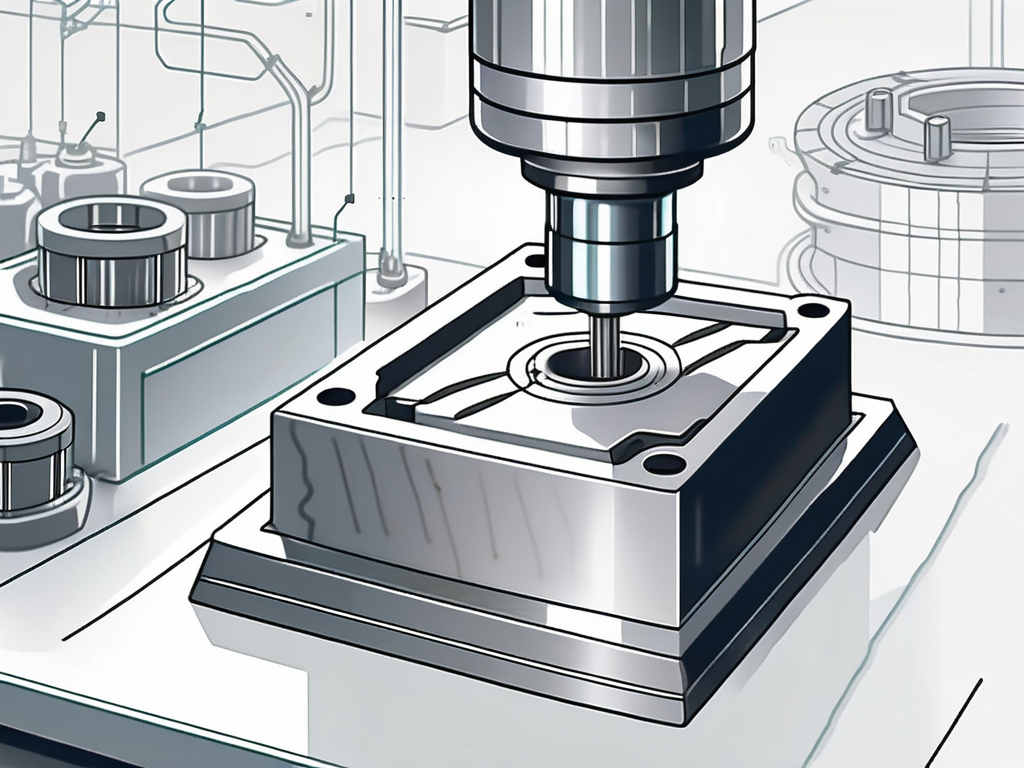

With the advancements in technology, the manufacturing of mouth guards has become more efficient and precise. Digital scanners are now used to capture detailed 3D images of the patient's teeth, eliminating the need for messy and uncomfortable physical impressions. These digital scans are then transferred to computer-aided design (CAD) software, where dental professionals can meticulously design the mouth guard to perfectly fit the patient's unique dental anatomy.

Once the design is finalized, the digital file is sent to a computer-aided manufacturing (CAM) machine, which uses state-of-the-art milling technology to fabricate the mouth guard from high-quality materials. This automated process ensures consistent and accurate results, enhancing the overall fit and comfort of the mouth guard.

Furthermore, the use of advanced materials, such as medical-grade thermoplastics, allows for increased durability and flexibility in mouth guard manufacturing. These materials are specifically designed to withstand the forces exerted during bruxism episodes, providing long-lasting protection for the teeth and jaw.

The Evolution of Mouth Guard Design

With advancements in dental technology, mouth guards have evolved significantly from their traditional designs. These innovations aim to provide superior comfort, fit, and functionality, ultimately improving the overall user experience.

As the demand for personalized healthcare solutions continues to rise, the field of mouth guard design has witnessed a notable shift towards customization. This personalized approach allows dental professionals to tailor mouth guards to meet the unique needs of each individual patient. By utilizing cutting-edge software and digital scanning tools, dentists can now create bespoke mouth guards that not only fit perfectly but also address specific dental concerns, such as bruxism or TMJ disorders.

The Shift Towards Customization

One of the significant trends in mouth guard design is the shift towards customization. Dental professionals now have access to state-of-the-art software and digital scanning tools that allow them to capture precise impressions of patients' teeth. These digital records can then be used to create custom-designed mouth guards that offer an unparalleled fit, improving patient comfort and compliance.

Furthermore, the integration of 3D printing technology has revolutionized the production process of custom mouth guards. This innovative manufacturing method enables dental laboratories to create intricate mouth guard designs with unmatched precision and efficiency. Patients can now benefit from lightweight, durable mouth guards that are specifically tailored to their dental anatomy, ensuring optimal protection and comfort during sleep.

Technological Advancements in Mouth Guard Design

The integration of advanced technologies, such as computer-aided design and manufacturing (CAD/CAM) systems, has significantly contributed to the evolution of mouth guard design. These technologies enable dental professionals to create intricately designed mouth guards with enhanced functionality and aesthetics. Additionally, CAD/CAM systems facilitate the use of biocompatible materials, ensuring optimal oral health and durability.

Moreover, the advent of smart mouth guards equipped with sensor technology represents the next frontier in oral healthcare. These innovative devices can track a patient's nighttime jaw movements and provide valuable data to dentists for treatment planning. By combining traditional craftsmanship with cutting-edge digital solutions, the future of mouth guard design holds immense potential for improving patient outcomes and revolutionizing the field of dental care.

Innovative Materials in Mouth Guard Manufacturing

Material selection influences the overall performance and longevity of mouth guards. Innovative materials have played a pivotal role in improving the efficacy and durability of these oral appliances.

As technology advances, researchers and manufacturers continue to explore cutting-edge materials that can revolutionize the field of mouth guard manufacturing. These materials not only enhance the functionality of mouth guards but also prioritize the user's comfort and oral health.

Exploring Biocompatible Materials

Biocompatible materials have gained popularity in mouth guard manufacturing due to their ability to mimic natural teeth properties and provide a comfortable fit. These materials are non-toxic, hypoallergenic, and resistant to wear, ensuring extended use without compromising oral health. Some examples of biocompatible materials commonly used in mouth guard manufacturing include medical-grade silicones, thermoplastics, and biocompatible resins.

In addition to their biocompatibility, these materials undergo rigorous testing to ensure they meet industry standards for safety and efficacy. Manufacturers collaborate with dental professionals and material scientists to fine-tune these materials, resulting in mouth guards that not only protect teeth but also promote overall oral well-being.

The Role of Durability and Comfort in Material Selection

When selecting materials for mouth guards, durability and comfort are key considerations. Newer materials offer improved strength, resistance to impact, and flexibility, ensuring longevity and protection against wear and tear. Moreover, these materials provide enhanced comfort, reducing irritation and discomfort experienced by the user.

By prioritizing both durability and comfort in material selection, manufacturers aim to create mouth guards that not only last longer but also feel more natural in the user's mouth. This focus on user experience drives innovation in material science, pushing the boundaries of what is possible in mouth guard manufacturing.

The Impact of Design Innovation on User Experience

Innovative designs in mouth guard manufacturing have significantly improved the user experience by addressing common challenges and ensuring optimal comfort, fit, and performance.

When it comes to design innovation in mouth guards, the focus is not only on comfort and fit but also on durability and ease of maintenance. Manufacturers are incorporating advanced materials that are not only comfortable to wear but also resistant to wear and tear, ensuring longevity and cost-effectiveness for users. Additionally, some innovative mouth guards come with special cases or cleaning solutions that make it easier for users to maintain hygiene and prolong the lifespan of their mouth guards.

Improved Comfort and Fit through Design Innovation

Design innovations have resulted in mouth guards that conform precisely to the individual's teeth and bite, eliminating discomfort and allowing for secure positioning during sleep. Features such as smooth surfaces, adjustable components, and ergonomic designs enhance overall comfort and prevent irritation, ensuring a more satisfying user experience.

Moreover, the use of cutting-edge technology, such as 3D scanning and printing, has revolutionized the customization process for mouth guards. By creating precise digital models of a user's teeth, manufacturers can produce mouth guards that offer unparalleled comfort and fit, tailored to the unique oral anatomy of each individual. This level of customization not only enhances comfort but also improves the overall effectiveness of the mouth guard in protecting against bruxism and related issues.

Enhancing User Compliance with Innovative Designs

Compliance with long-term mouth guard usage is crucial for managing bruxism effectively. The introduction of innovative designs has made mouth guards more aesthetically appealing and user-friendly. Sleek and discreet designs encourage users to wear their mouth guards consistently, leading to better protection and ultimately improving oral health outcomes.

Furthermore, some modern mouth guards come equipped with smart technology features that track usage and provide feedback to users. These devices can monitor factors such as grinding intensity and duration, helping users understand their habits and progress in managing bruxism. By incorporating elements of gamification or personalized feedback, these innovative mouth guards motivate users to adhere to their treatment plans and actively engage in improving their oral health.

Future Trends in Mouth Guard Manufacturing

The field of mouth guard manufacturing continues to evolve, with ongoing developments promising further advancements in design and production.

The Potential of 3D Printing in Mouth Guard Manufacturing

3D printing has emerged as a game-changer in the field of dentistry, and its potential impact on mouth guard manufacturing is undeniable. This technology allows for the creation of intricate and customized mouth guards with superior precision and reduced fabrication time. With further advancements in 3D printing materials and technology, mouth guards may become even more accessible and tailored to individual patient needs.

The Role of AI and Machine Learning in Design Innovation

Artificial intelligence (AI) and machine learning (ML) are poised to revolutionize the design process of mouth guards. These technologies can analyze vast amounts of data, including patient records and dental images, to generate innovative designs and optimize the fit and performance of mouth guards. The integration of AI and ML algorithms into the manufacturing workflow holds tremendous potential for enhancing the overall effectiveness and efficiency of mouth guard production.

Innovative designs in mouth guard manufacturing have transformed the landscape of oral health care. Through technological advancements and material innovation, these dental appliances have become more effective, comfortable, and personalized. As technology continues to evolve, the future of mouth guard manufacturing looks promising, with advancements such as 3D printing and AI-driven design poised to further enhance the functionality and user experience of these indispensable oral devices.